Things you may not know about Fiber Laser Ceramic Ring

Fiber Laser Ceramic Ring is an essential component of laser cutting systems. They help focus the laser beam onto the material being cut, ensuring accurate and efficient cuts.

What is ceramic laser cutting?

Fiber Laser Ceramic Ring is positioned on the laser cutting head, situated above the laser nozzle and below the sensor. Its primary function is to transmit and gather the cutting signal that the nozzle emits, ensuring that the nozzle avoids contact with the plate during operation.

Fiber Laser Ceramic Ring is an important and vulnerable part of the laser cutting head

This precaution of Laser Cutting Adapter safeguards the cutting head from potential damage. Notably, the ceramic ring exhibits enhanced resistance to high temperatures and deformation.

Description of fiber laser ceramic ring

Fiber Laser Ceramic Ring is an important and vulnerable part of the cutting head of a ceramic laser cutting machine. This is also a type of accessory that can be replaced when damaged or after being used for a long time. The primary composition of the laser cut ceramic comprises three key elements:

Ceramic Body: The ceramic body is typically made from one of two commonly used materials, namely ZrO and AlO. ZrO is more expensive in the Chinese market due to its small coefficient of thermal expansion (high-temperature resistance), high density (wear and tear resistance), and excellent electrical resistivity. This type of ceramic body effectively guarantees insulation for critical components and the cutting head, reducing wear on the cutting head. While using AlO can be a cost-saving measure, it does result in shorter replacement intervals for susceptible components.

Stainless Steel Sheet: Metal is generally utilized for signal transmission. The contact point between the stainless steel parts and the laser nozzle accurately and swiftly conveys electrical signals to the copper needle.

Copper Column: Copper columns (also known as copper needles) serve as intermediaries for relaying electrical signals collected by the stainless steel sheets to the internal transmission line of the ceramic laser cutting head. This ensures adaptability for the controller. Effective electrical signal propagation demands high electrical conductivity, making gold plating an efficient technique.

Additionally, the use of conductive silver glue for adhesion is crucial. It securely bonds these three components of ceramic rings, maintaining overall conductivity even at high temperatures, ensuring the laser head's safe operation. High-quality ceramics minimize disruptions to the original laser path after replacement, eliminating the need for readjustment and saving time and effort.

Silver glue is required to attach the three parts of the Fiber Laser Ceramic Ring

Over time, older fiber laser ceramic in the market frequently suffer from poor contact between stainless steel parts and copper needles. In severe cases, the copper needles can break, resulting in unstable signals or even signal loss, causing unexpected interruptions in ceramic laser cutting machine operation. High-quality stainless steel components, when properly assembled with appropriately sized ceramic bodies, help maintain excellent concentricity. This reduces concentricity errors when replacing the nozzle in the laser cutting machine.

Classification of fiber laser ceramic rings

There are four primary categories of Fiber Laser Ceramic Ring used in laser cutting machines.

Alumina Fiber Laser Ceramic Ring

These four categories of Laser Cutting Ceramic Connector cater to different requirements in laser cutting, offering a range of properties and cost considerations.

Zirconia: These are recognized for their exceptional mechanical properties, such as impressive strength, resistance to wear and corrosion, and overall durability. They can also handle abrupt temperature fluctuations effectively. The main drawback probably is their relatively higher cost than the others.

Alumina: These laser ceramic rings are commonly employed by manufacturers in laser cutting machines due to their electrical insulation, wear resistance, and strong thermal conductivity. They are a more cost-effective option compared to zirconia. However, they are susceptible to cracking under rapid temperature changes, which are common in laser metal cutting machines.

Silicon Nitride: While this laser cut ceramics come at a higher price point, they offer several advantages, including temperature stability, superior resistance to fracturing, and low thermal expansion. Additionally, they exhibit remarkable resistance to oxidation, corrosion, and regular wear.

Silicon Carbide: Despite being prone to breakage or cracking under stress or impact, this Laser Cutting Adapter comes with notable benefits. This ceramic ring for fiber laser cutting machine can include good wear resistance, high hardness, and efficient thermal conductivity. They are also reliable in handling temperature fluctuations with ease.

Here are some types of China Laser Cutting Ceramic Rings currently available at LECI:

Ceramic WSX D28: Diameter: 28*24.5mm; Thread: 11m; Material: Alumina Ceramic; Height: 11.7 mm; Usage : D28 Precitec/ WSX/ Ospri

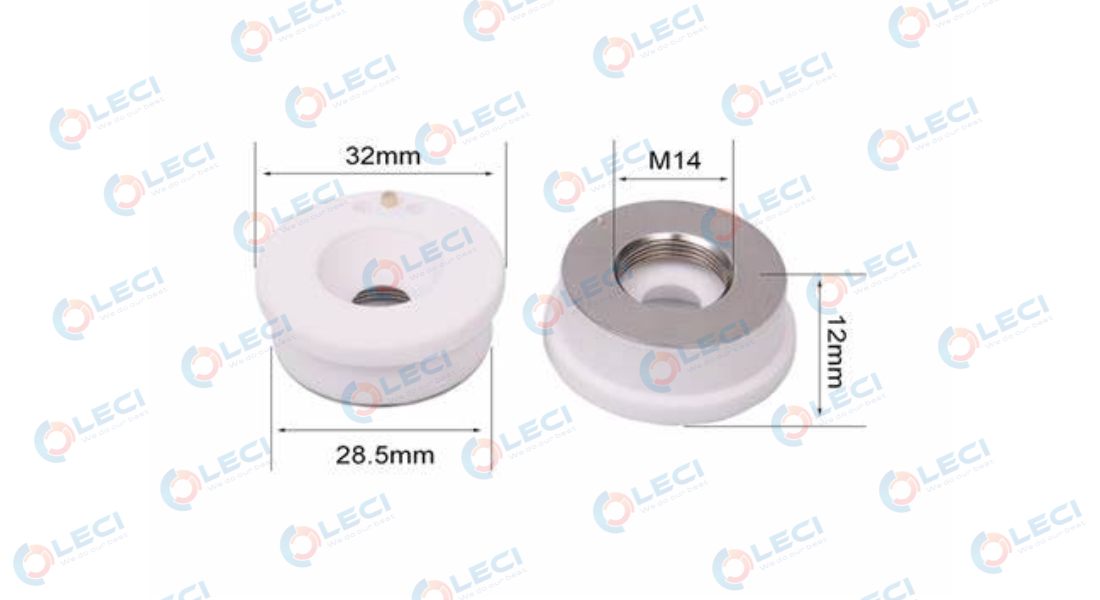

Ceramic Raytool D32: Height: 12mm; Upper diameter 32mm; Bottom diameter 28mm

Ceramic Highyag: Origin China; Production Capacity: 50000

Ceramic Porad: Large diameter: 31 mm: Height: 13.5 mm; Thread: 11mm

Ceramic BOCI: Large diameter: 41 mm; Height: 34 mm; Thread: 11mm

Ceramic Raytool 3D: There are two types: 32/38.5 mm and 19.5/16 mm.

LECI - a reputable supplier of ceramic fiber laser rings

Over time, any type of machinery will inevitably experience component wear and tear, which can impact the machine's productivity. Therefore, regular inspection, maintenance, and scheduled component replacements are crucial. You can explore the range of ceramic rings

for fiber laser cutting machines currently available at LECI to make an informed choice.

LECI - a reputable supplier of Fiber Laser Ceramic Ring

Why should you choose LECI?

Professional Staff: LECI boasts a team of technical experts with over 15 years of experience, having previously held chief engineering positions in prominent industry-leading enterprises. This team will enthusiastically replace the Fiber Laser Ceramic Ring for your machine.

Timely Component Support: LECI maintains readily available component inventory, such as Laser Cutting Ceramic Connector, ensuring that when faults or component failures are detected, customers need not worry about production interruptions.

Round-the-Clock Assistance: LECI is always ready to assist customers 24/7, regardless of location, to ensure efficient machinery repairs.

Prioritizing Trust: For LECI, "trust" is our top priority and the fundamental prerequisite for our operations and business growth. Consequently, we pledge to deliver the highest quality and the finest products to our customers when they engage with our services.

Contact us now to buy China Laser Cutting Ceramic Rings:

Address: Room 1901, Saigon Trade Center Tower, 37 Ton Duc Thang, Ben Nghe Ward, District 1, Ho Chi Minh City, Viet Nam.

Phone: 02822202988

Hotline: (+84) 901441689 (Whatsapp)

Website: www.lecilaser.com